What is a wool pile weatherstrip?

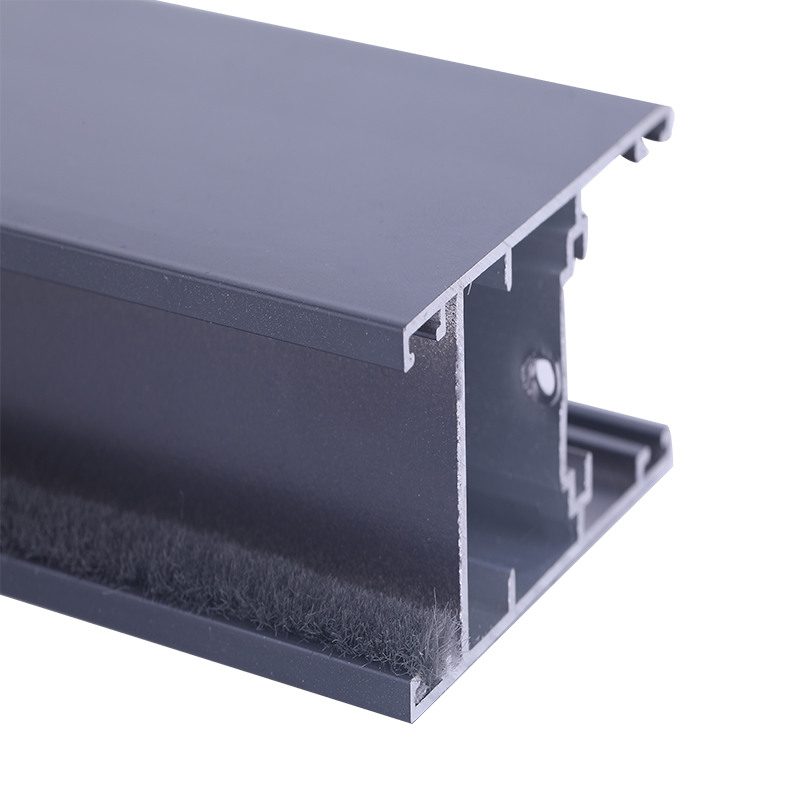

IT is made of high-quality atactic polypropylene, with siliconized polypropylene fibre and polypropylene film synthesis, unique design, is applied to doors, windows, furniture, vacuum cleaners and other sealed high-grade products.

What is the function of pile weatherstrip?

The wool pile weatherstrip plays an important role in water tightness, airtightness and energy saving in plastic steel doors and windows. According to the function and use requirements of the sealing strip, it must have sufficient tensile strength, good elasticity, good temperature resistance and ageing resistance. The structural size of the cross-section should match the profile of the plastic steel doors and windows. The wool strips are mainly used for sealing between frames and fans. It is generally used in the window sash, around the frame fan or on the sealing bridge to enhance the seal between the frame and the fan

How to choose the right pile weatherstrip?

The specification and size is an important factor that affects the performance of sliding doors and windows and water tightness, as well as the opening and closing force of doors and windows. If the wool pile height is too big or too high, it is not only difficult to assemble but also makes the moving resistance of doors and windows increase, especially the first resistance when opening and the least resistance when closing. Too small specifications or the height of the pile is not enough, easy out of the slot so that the door and window sealing performance greatly reduced. The wool pile must be silicified, the quality of wool pile appearance for the surface is straight, the bottom and vertical hair smooth, no bending, there is no pitting on the bottom plate to meet the requirements of 0.20 mm.

Various Types of Wool Pile Weatherstrip

Silicone/non-silicone pile weatherstrip seal

Wool pile weatherstrip is processed in different ways. Sealing strips can be divided into siliconized and non-siliconized. The siliconized sealing strip is made of polypropylene fibre treated with silicone oil. The sealing strip after silicone oil treatment can significantly improve the waterproof performance of doors and windows, while the ageing resistance, flexibility, and lodging resistance have been significantly improved. The industry standard JC / T635-1995 clearly states that the sealing strip must be siliconized.

Fin/Without fin pile weatherstrip seal

From the structure, the sealing strip can be divided into ordinary type and intermediate sandwich type. On the basis of the former, a polyethene film or siliconized non-woven fabric is added in the middle of the sealing wool to completely isolate the airflow between the gaps of the sealing wool, so the sealing performance of the intermediate sandwich sealing strip is 5 times better than that of the ordinary sealing strip the above. The air permeability of the doors and windows made of it can reach the highest national standard.

contact us

Company: Sichuan Jiayueda Building Materials Co., Ltd.

Contact: grace Lee

Email: gracelee@jyd-buildingmaterials.com

WhatsApp: +86 173 4579 3501

Post time: May-27-2022